Rotary Packing Machine (doypack & zip pouch)

Min.Order / Reference FOB Price: US 500-100,000/Piece

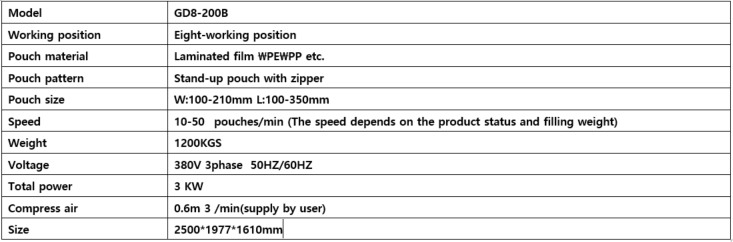

| Automatic Grade: | Automatic |

| Application: | Cosmetics, Drinks, Skin Care Products, HairCare Products, Oil |

| Type: | Packing Machine |

| Forming Species: | Bag Moulding |

| Forming Function: | Forming, Filling, Seal |

| Driven Type: | Electric |

| Model NO.: | GBD-200B/250B/300B |

| Material Type: | Powder, Liquid, Solid, Granule |

| Packaging: | Bag |

| Packaging Material: | Plastic |

| Dimensions: | 2500*1977*1610mm |

| Total Power: | 3 Kw |

| Weight: | 1200kg |

| Trademark: | UNIMACH |

| Transport Package: | Wooden Case |

| Specification: | 2500*1977*1610mm |

| Origin: | Chin |

| Product Description |

| Function and characteristics |

| 1. Easy to operate, adopt advanced PLC from GermanySiemens, mate with touch screen and electric control system, the man-machineinterface is friendly. 2. Frequency conversion adjusts the speed: This machine uses frequencyconversion equipment, can be adjusted within the range according to the needsof reality in production. 3. Automatic checking: No pouch or pouch open error, no fill, no seal. The bagcan be used again, avoid wasting packing materials and raw materials. 4. Safty device: Machine stop at abnormal air pressure, heater disconnectionalarm. 5. Horizontal conveyer style to giving bag: It can put on more bags on the bagstorage and have a low requirement about the quality of bags. 6. The width of the bags could be adjusted by electrical motor. Press thecontrol-button could adjust the width of all clips, easily operate, and rawmaterials. 7. Use the plastic bearing, don't need put on oil, less pollution. 8. Use no oil vacuum pump, avoid polluting the environment in the production. 9. The opening zipper framework is special in the feature of zipper bag, it canavoid distortion or destroy when open the zipper 10. The packing materials loss low, what this machine is used the preformedbag, the bag pattern is perfect and has a high quality of the sealing part,this improved the product specification 11. Product or packing bag contact parts adopt stainless steel or othermaterials which accord with the food hygienic requirements, guarantee hygieneand security of the food 12. With different feeders changed to pack solid, liquid, thick liquid, powderand so on. 13. The packing bag suits in extensive range, suit for multi-layer compound,monolayer PE, PP and so on Preformed bag made by film and paper. |

| Product Process |

| 1. Giving bag 2. Coding date 3. Open bag 1st (open the zipper) 4. Open bag 2nd (integrity open the bottom of bag) 5. Filling & vibrate 6. Reserve 7. Exhaust and sealing 8. Forming & output packages. |