|

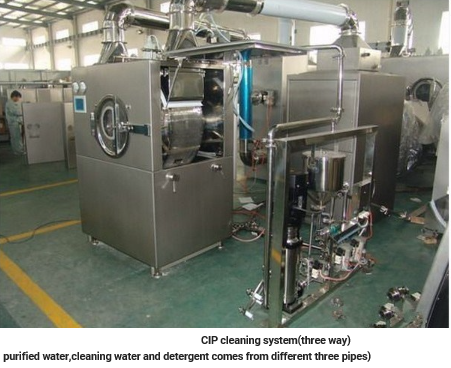

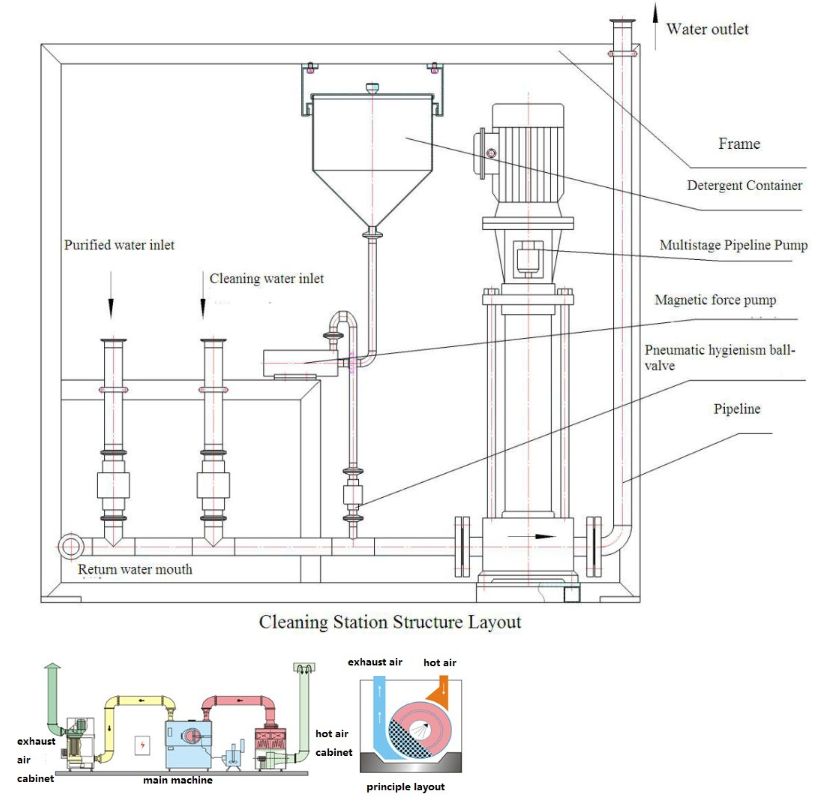

With CIP online cleaning system, the D- type coating machines inaddition to possess all the functions and characteristics of the C-typemachine, but also have the following characteristics:

1. Different parts of the main machine collocatedwith a number of nozzles for cleaning machine on-line.

2. Configured the independent cleaning liquid booster distribution station tomake sure the pressure of cleaning liquid form every spray header get up to0.6Mpa and wash the coating machine effectively.

3. Configured the cycle cleaning and drainage systems for the cleaning processto choose

4. Under the control of the PLC, can program a number of cleaning procedures

5. Under the control of the PLC, dry the remanent water of each nozzle bycompressed air.

6. Under the control of the PLC, implement fully automatic washing and dryingprocess. |

|

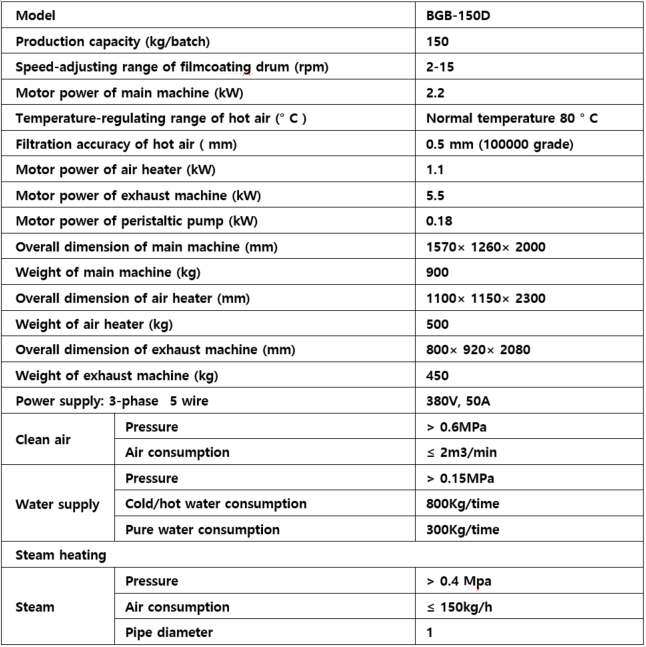

Main technical parameters of BGB-D type coating machine (with CIP): Performance

1. The control system consists of PLC and HMI. Thedesign is reasonable

And programming is flexible, which are adapt to the different needs ofpharmaceutical technology, thus featuring reliable work, stable performance andconforming to the requirement of GMP.

2. Under the action of the agitation of streamline guide plate, the tabletcores are tumbling smoothly and exchanging frequently, thus elimination thephenomenon of tablet cores falling from a high place and the collide, so thatsolve the problems of broken pieces and chipped edged and also improve the rateof finished products. The narrow surface of the guide plate eliminates theadhesion of coating material on its surface, thus saving the coating materialand improving the quality of medicine.

3. The peristaltic pump with constant pressure and variable eliminates the needfor a return pipe. The turning radius of the drum varies with the pressure. Theslurry output and the quantity of slurry sprayed are balanced from plugging-up,and saving the coating material, moreover the cleaning is simple, without deedcorner.

4. The spray gun is specially designed for film coating machine with evenatomization and large coverage of spraying. The universal adjustable spray headmakes the cleaning mechanism of spray gun unaffected by charge quantity, sothat coating can proceed continuously, thus reducing the coating time andsaving coating material.

5. Display and control the negative pressure in the coating drum

We have set up a negative pressure detecting point in the upper box of thecoating machine and installed a 2300-1kpa pressure differential gauge(made bythe USA Dwyer Co) on the operating console, operator can operate the touchscreen according to the technological specification (for instance, the negativepressure being 10PA), and control the speed of exhaust fan, so as to controlthe negative pressure in the drum.

6. Display and control of the speed of heat-supply air

We have set up an air-speed detecting point in the heat-supply air pipe andinstalled a 2001AV air speed gage(made by the USA Dwyer Co. )on the operatingconsole, the operator can operate the touch screen according to thetechnologically specified air speed value(8m/s), so as to control the speed ofhot air fan and meet the demand for air supply.

7. Display and control of temperature value

Temperature sensors are installed at the air inlet and outlet of thefilmcoating machine. After the temperature signal is inputted to the PLC andcompared with the set value(90), the heat exchange is automatically controlled,thus achieving the control of filmcoating temperature value. |