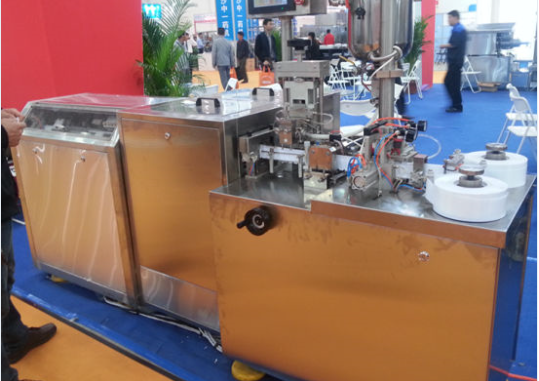

Zs-1 Full-Automatic Suppository Filling Sealing Machine

| Type: | Pharmaceutical Packaging Machinery |

| Finished Dosage Form: | Suppository |

| Precision: | High Precision |

| Certification: | CE, GMP |

| Voltage: | 380V |

| Computerized: | Computerized |

| Basic Info | |

| Model NO.: | ZS-1 |

| Condition: | New |

| Trademark: | UNIMACH |

| Transport Package: | Wooden Case |

| HS Code: | 8424303090 |

| Warranty: | 1 Year |

| Customized: | Customized |

| Specification: | ZS-1 |

| Origin: | China |

| Product Description: |

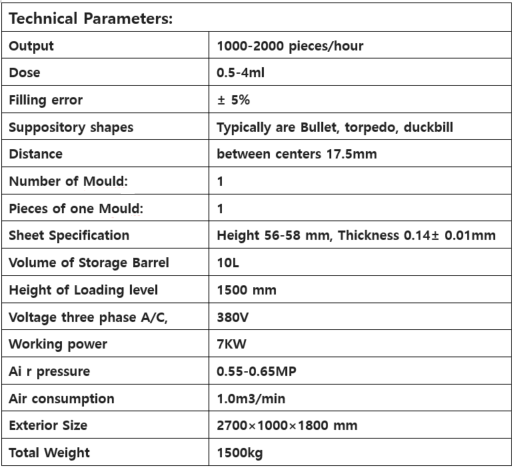

| 1000-2000 pieces per hour / Suitable for smallscale company / Fully automatic and plc control / Servo motor is used |

| Machine Details: |

| In order to meet the requirement of university,research institute or any company at lab scale production, we developed theZS-1 automatic suppository machine. This unit is composed by four parts whichare shell forming part, cavities filling part, suppositories cooling and condensingpart and sealing part. The whole process operates automatically and controlledby PLC. The working process is illustrated as below: PVC, PVC/PEsheet-----welding-----pre-heating-----knurling-----blowing andforming-----filling-----cooling and condensing-----pre-heating-----sealing-----embossing----trimming-----counting and cutting-----finished products |

| Working Principle: |

| Bundles of PVC or PVC/PE sheet are transformed intoshells ready for filling by shell forming machine. These shells are then movedinto the station for filling. The well blended liquid medicine is injected intothe shells controlled by a high accuracy measuring device. Plug in filling isemployed to make sure no air bubbles, spilling or leaking. After filling, thebelts will enter into the cooling boxes. The liquid medicine will move along aspecial curve and cold circulating water is used for cooling. The liquidmedicine will transform to solid state after this stage...The cavitiescontaining the solid suppositories are then moved to sealing station. Aftersealing, products will be conveyed to the embossing station where informationsuch as batch number, date of manufacture and expiry will be embossed. Afterembossing, the belts will go for cutting. Products can be cut by any numberaccording to customer's requirement. |