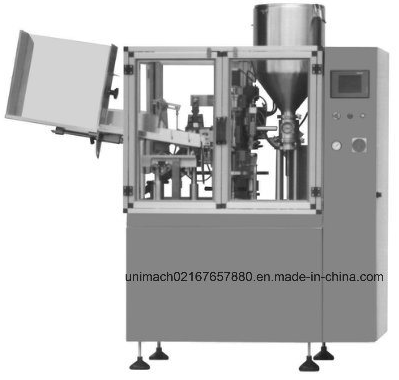

Automatic Plastic Tube Filling Sealing Machine

Min.Order / Reference FOB Price: US $15,000-35,000/Piece

| Type: | Filling and Sealing Machine |

| Usage: | Outpacking |

| Application: | Cosmetics, Drinks, Oil, Skin Care Products,Hair Care Products |

| Packaging Material: | Plastic |

| Automatic Grade: | Automatic |

| Packaging: | Tube |

| Model NO.: | NF-60A |

| Material Type: | Liquid, Cream |

| Trademark: | UNIMACH |

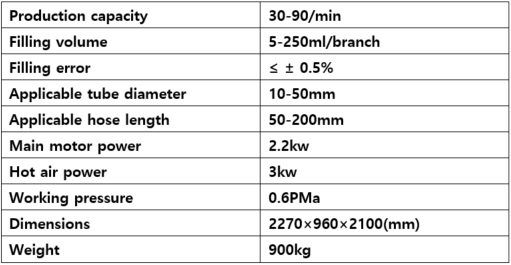

| Specification: | 2270 * 960 * 2100 ( mm) |

| Packaging Material Mechanical Properties: | Full Automatic Filling and Sealing Machine |

| Dimensions: | 2270 * 960 * 2100 ( mm) |

| Transport Package: | Wooden Case |

| Origin: | China |

| Product Description |

| 1.suit for plastic tube, plastic composite tube fillingand sealing 2.automatic/semi-automatic |

|

The control parts of the machine are composed ofintelligent man-computer interface, large touch screen display/operationcontrol panel, including temperature setting, motor speed, filling speed,direct screen display and screen control. The components of the machine whichtouches the filling material are made of stainless steel SUS304 and SUS316L.Transparent cover, feeding hose, feeding device are also supplied with themachine. The machine is featured with safety switch, auto-stop, soft tubepositioning, photoelectric sealing control etc. During the process, hosefeeding and setting, filling and sealing, ejecting are all auto maticallycontrolled. Digital count device is installed at the low front part of themachine. During filling process the filling head is put inside the material potto avoid air-entrance. For high viscosity filling material, blow-off device isinstalled to ensure a complete sealing. Many choices of sealing type areavailable to meet different need of clients. |

| Mainfeatures: |

| 1. the following transmission part enclosed in theplatform, safe, reliable, non-polluting; 2. filling and sealing parts mounted on the platform above semi-closedstatic frame viewing hood, easy to observe, easy to operate, easy tomaintenance; 3. PLC control, man-machine conversation interface; 4. Circuitous dial to cam drive, high speed, high precision; 5. Box and Inclined tube position, optionally; 6. Crved armrest with a vacuum adsorption unit, handrails and pressuretube device interaction, the hose is fed into the upper tube station; 7. Photoelectric standard workstations, high-precision sensor, steppermotor control hose pattern in the correct position; 8. Movable injection materials head deep inside the hose injectionmaterial, side exit side note, the end of injection material delivery nozzlewith integrated manner to ensure filling blow cut quality; 9. No tube no filling; 10. Sealing adoption (Leister hot air gun) tail pipe internal heating,cooled by cooling means external configuration; 11. The workstation automatically typing the code number printed on the processrequirements of the position; 12. Cut plastic robot at a right angle or a rounded end of the hose forselection; 13. Fault Baojing, no pipe alarm, the door opened shutdown, overloadshutdown; 14. Counting and quantitative downtime; |